Compressed Air

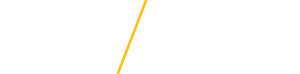

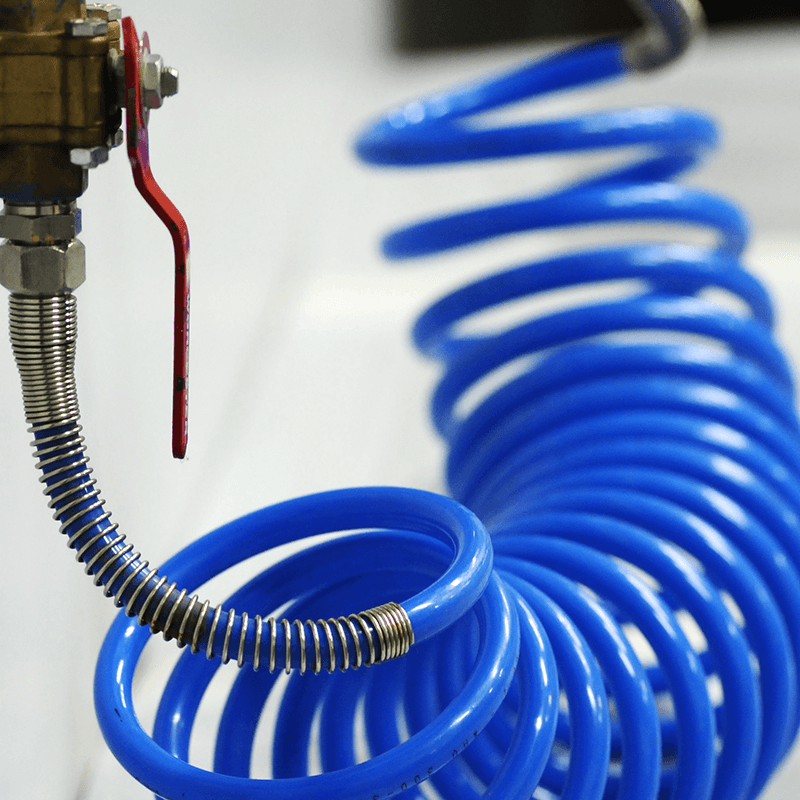

Compressed air is often called the “fourth utility,” after electricity, natural gas and water. Approximately 70% of all manufacturers having a compressed air system and up to 30% of electricity consumed by the manufacturing sector can be attributed to compressed air usage.

For many, this system is a vital input in production widely used due to its cleanliness, availability and ease of use. However, compressed air systems are highly inefficient, resulting in significant wasted energy and costs. It is estimated that 25% of compressed air is wasted through leaks!

Effects of Air Loss

As with any wasted product, wasting compressed air:

- Reduces system reliability

- Wastes energy

- Decreases productivity

- Costs money!

After completion of a 6-month pilot project by the Iowa Economic Development Authority (IEDA), the IWRC identified the financial and energy savings IA small businesses could save if compressed air leaks are fixed.

Money and Energy Wasted through Compressed Air Leaks

After conducting 87 audits at Iowa small businesses to identify and tag compressed air leaks, the IWRC was able to determine the actual cost and energy wasted through compressed air leaks. Outcomes showed a range of results depending on type and size of business. For example, one body show had only one leak, while 47 leaks were identified at a structural steel fabricator.

While a potential for energy savings and air emission reductions exist, the most valuable outcome for the business is cost savings. Through compressed air audits the IWRC identified a total annual cost savings of $270,254 for the 87 participating businesses.

The Compressed Air Leak Pilot Project was funded by a state energy grant from the Iowa Economic Development Authority. The project was completed during a six-month timeframe throughout 2014.